Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Introduction

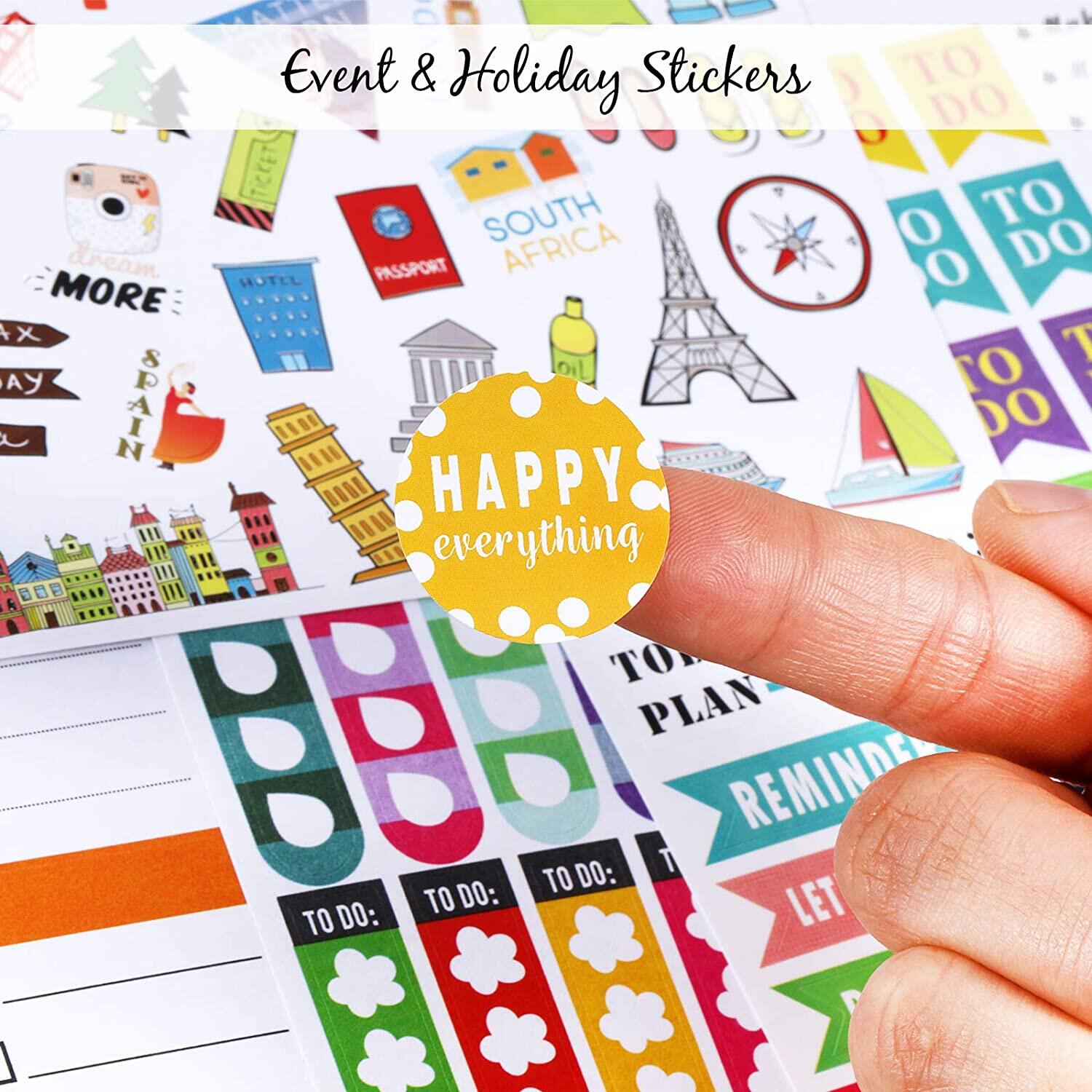

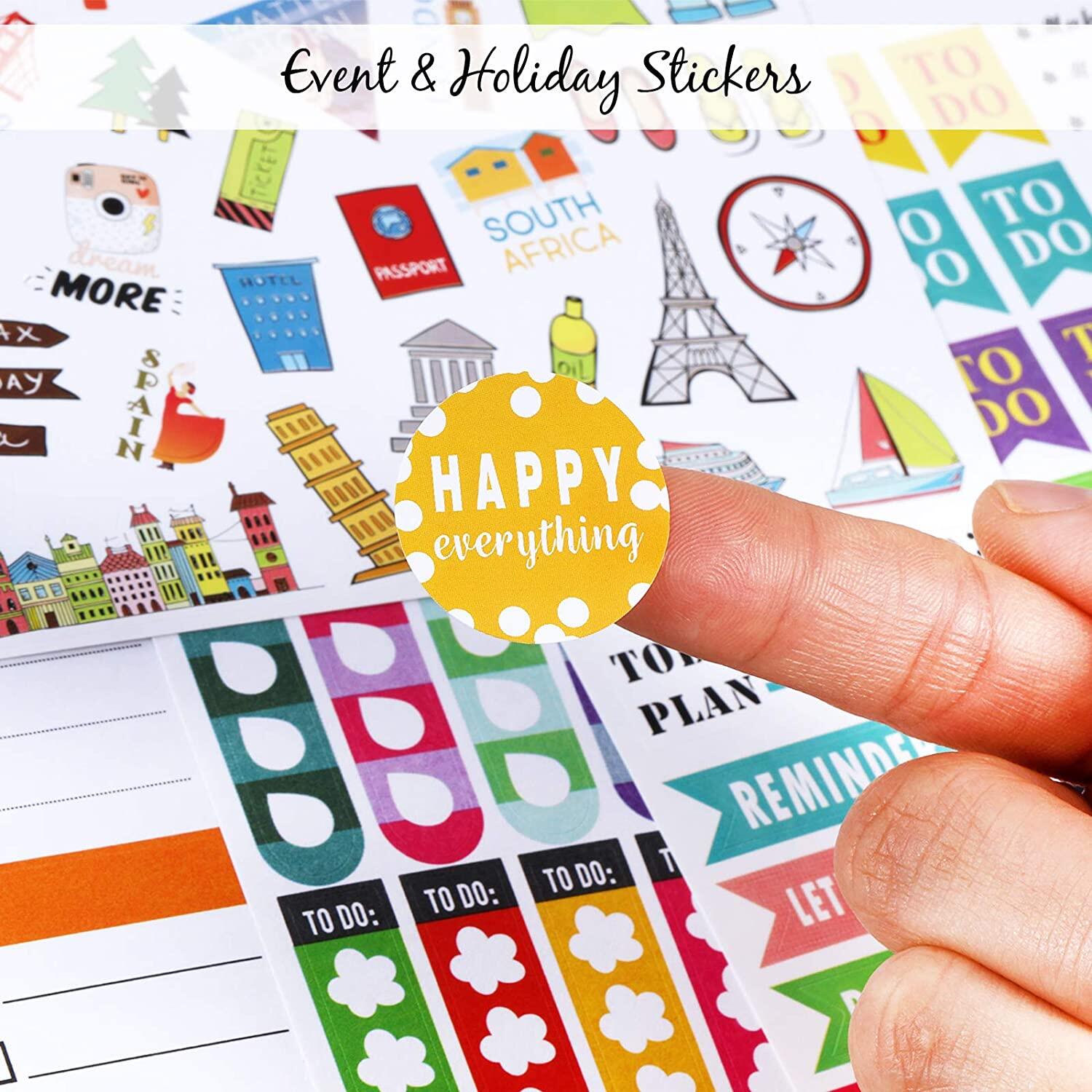

Custom die-cut stickers have become increasingly popular in various industries due to their versatility and ability to enhance brand visibility. In this blog post, we will explore the material selection process, applications, pricing, and cost control methods, as well as the different printing techniques and effects associated with custom die-cut stickers.

Material Selection

When it comes to material selection for custom die-cut stickers, several factors need to be considered, including durability, adhesion, and appearance. Here are some commonly used materials:

Vinyl: Vinyl stickers are highly durable, weather-resistant, and suitable for both indoor and outdoor applications. They are available in various finishes, such as glossy, matte, or transparent. Vinyl stickers are also known for their excellent adhesive properties, making them ideal for long-term use.

Paper: Paper stickers are cost-effective and ideal for indoor use. They are available in different finishes, including glossy, matte, or textured. Paper stickers are easy to print on and can be easily written on, making them suitable for labelling purposes.

Polyester: Polyester stickers offer excellent durability and resistance to water, UV rays, and chemicals. They are commonly used for outdoor applications where exposure to harsh conditions is expected. Polyester stickers are available in various finishes and can be printed with vibrant colours.

Applications and Uses

Custom die-cut stickers have a wide range of applications across various industries. Some common uses include:

Branding and Marketing: Custom die-cut stickers are an effective way to promote brands, products, or services. They can be used on packaging, promotional materials, vehicles, and more. Stickers with unique shapes and designs can help create a memorable brand image.

Product Labelling: Die-cut stickers can be used as product labels, providing important information such as ingredients, instructions, and branding. They can be easily applied to various surfaces, including bottles, jars, and packaging.

Event Promotion: Stickers can be used to promote events, such as concerts, festivals, or trade shows. They can be distributed as giveaways or used for ticketing purposes. Custom die-cut stickers with event-specific designs can help create excitement and generate interest.

Pricing and Cost Control Methods

The pricing of custom die-cut stickers depends on several factors, including material, size, quantity, and complexity of the design. Here are some cost-control methods to consider:

Bulk Ordering: Ordering stickers in larger quantities often leads to lower unit costs. Consider estimating your long-term sticker needs and placing a bulk order to save on costs. This is particularly beneficial for businesses that require a consistent supply of stickers.

Simplify the Design: Intricate designs with multiple colours and complex shapes can increase the production cost. Simplifying the design can help reduce costs without compromising the overall impact. Focus on essential elements that convey your message effectively.

Material Selection: Opting for cost-effective materials, such as paper stickers for indoor use, can help lower the overall cost. However, ensure that the chosen material meets the required durability and adhesion standards for your specific application.

Printing Techniques and Effects

Custom die-cut stickers can be printed using various techniques, each offering unique effects. Here are some commonly used printing techniques:

Digital Printing: Digital printing is a versatile and cost-effective method suitable for small to medium-sized orders. It offers vibrant colours and allows for intricate details.Digital printing is ideal for designs with gradients, shadows, and complex artwork.

Offset Printing: Offset printing is ideal for large-scale orders. It provides high-quality, consistent results and is suitable for complex designs with spot colors. Offset printing offers precise colour matching and is often used for printing stickers with corporate logos and branding elements.

Screen Printing: Screen printing is a popular choice for stickers that require vibrant colours and high durability. It is suitable for both indoor and outdoor applications. Screen printing offers excellent colour saturation and can be used to print stickers on various materials, including vinyl and polyester.

Conclusion

Custom die-cut stickers makers like us offer endless possibilities for branding, marketing, and personal expression. By carefully selecting the right materials, understanding their applications, considering cost control methods, and exploring different printing techniques, you can create eye-catching and durable stickers that effectively convey your message. Whether you’re a business owner, event organiser, or simply looking to add a personal touch, custom die-cut stickers are a versatile and cost-effective solution. Embrace the creativity and impact that custom die-cut stickers can bring to your projects.