Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Introduction:

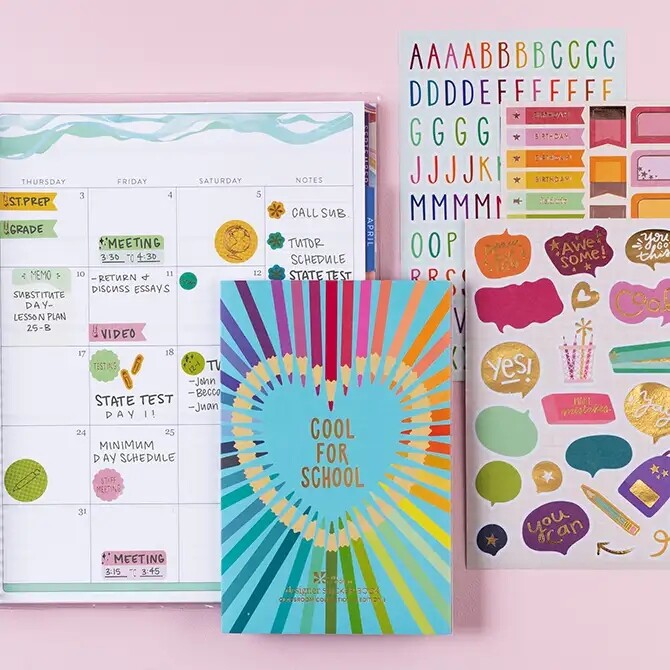

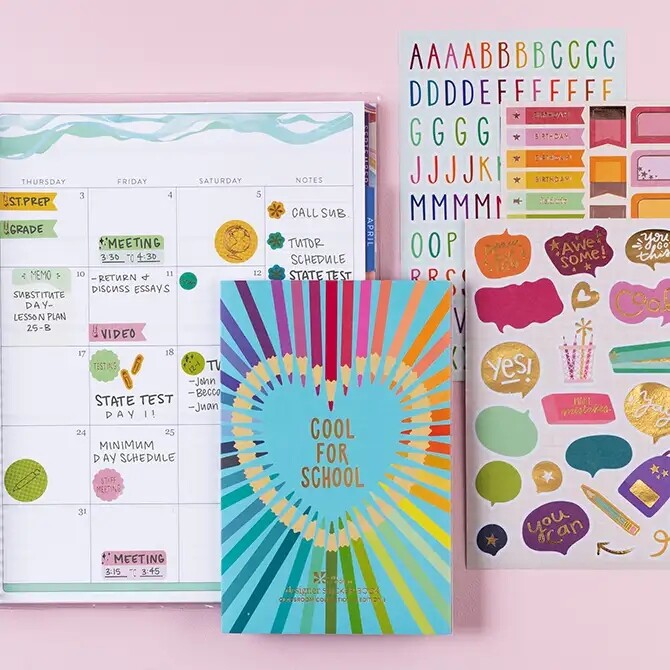

In the realm of sticker design and printing, achieving the perfect balance of quality and durability is paramount. Whether it's for personal use, branding, or promotional purposes, kiss-cut stickers have emerged as a versatile and popular choice. This article delves into the intricacies of what constitutes high-quality kiss-cut stickers, the importance of durability testing, the significance of waterproof and weather-resistant properties, technical insights into the printing process, and common pitfalls to avoid in both the design and ordering processes.

Kiss-cut stickers are more than just adhesive pieces of paper; they are a canvas for creativity and expression. But what sets apart a high-quality kiss-cut sticker from the rest? It all starts with meticulous material selection and manufacturing processes. Quality stickers are crafted using premium materials such as vinyl or polyester, ensuring longevity and resistance to wear and tear. Additionally, state-of-the-art printing techniques like digital printing with UV-resistant inks contribute to vibrant colors and crisp details, elevating the overall aesthetic appeal of the stickers.

A sticker's journey doesn't end with the printing press; it's just the beginning. Rigorous testing procedures are essential to guaranteeing durability and longevity. In specialized laboratories, stickers undergo a battery of tests, including adhesion strength tests, abrasion resistance tests, and exposure to various environmental conditions such as heat, humidity, and UV radiation. These tests simulate real-world scenarios to ensure that the stickers can withstand the rigors of daily use without fading, peeling, or deteriorating prematurely.

One of the hallmark features of high-quality kiss-cut stickers is their ability to withstand the elements. Whether adorning a water bottle, laptop, or outdoor signage, waterproof and weather-resistant stickers are indispensable. They not only retain their vibrant colors and adhesive properties when exposed to moisture but also stand firm against the onslaught of wind, rain, and sunlight. This resilience ensures that your message remains intact and visible, rain or shine, making them ideal for both indoor and outdoor applications.

Printing Process and Production

Behind every meticulously crafted kiss-cut sticker lies a sophisticated printing process. Digital printing technology has revolutionized the sticker printing industry, allowing for unparalleled precision and versatility. Using high-resolution printers and UV-resistant inks, intricate designs and vibrant colors are transferred onto the sticker material with stunning clarity and detail. The kiss-cutting process, which involves cutting through the sticker's top layer without penetrating the backing paper, adds an extra layer of intricacy and professionalism to the final product.

Application of Vector and Raster Images

When it comes to sticker design, understanding the difference between vector and raster images is crucial. Vector graphics, composed of mathematical equations and geometric shapes, offer scalability and crispness, making them ideal for logos, icons, and text. On the other hand, raster images, made up of pixels, excel at capturing complex textures and gradients, making them perfect for intricate illustrations and photographs. By leveraging the strengths of both types of images, designers can create captivating and visually appealing sticker designs that leave a lasting impression.

File Preparation Tips

Preparing files for printing is an often-overlooked aspect of the sticker production process, yet it can significantly impact the final outcome. Designers must adhere to specific file format and resolution requirements to ensure optimal printing results. Additionally, color management and printer calibration play a crucial role in maintaining color accuracy and consistency across different printing runs. By following best practices in file preparation, designers can minimize the risk of printing errors and ensure that their designs translate seamlessly from screen to sticker.

Common Mistakes in the Design Phase

In the realm of sticker design, even minor errors can have a significant impact on the final product's quality. Common mistakes include overlooking layout and dimension requirements, which can result in improper alignment or trimming issues during the printing process. Similarly, poor color choices and mismatched color profiles can lead to inaccurate color reproduction, detracting from the overall visual appeal of the stickers.

Common Mistakes in the Ordering Process

When placing an order for kiss-cut stickers, attention to detail is paramount to avoid costly mistakes. Choosing the wrong materials or finishing options can affect the sticker's durability and aesthetics, compromising its longevity and visual impact. Furthermore, overlooking critical details in the ordering process, such as quantity, size, and shipping preferences, can lead to delays and discrepancies in the final product.

Troubleshooting and Solutions

Despite meticulous planning and preparation, issues may arise during the sticker production process. In such cases, effective troubleshooting strategies are essential to identify and address the root cause of the problem. Whether it's reevaluating design requirements, communicating with the supplier, or exploring alternative printing solutions, proactive problem-solving ensures that any setbacks are swiftly resolved, minimizing disruption and ensuring a successful outcome.

Conclusion:

In the competitive world of sticker design and printing, quality and durability are non-negotiable. From meticulous material selection and manufacturing processes to rigorous testing and technical precision, every aspect of the sticker production process plays a crucial role in delivering a superior product. By understanding the nuances of high-quality kiss-cut stickers and avoiding common pitfalls in design and ordering processes, designers and businesses can elevate their brand and leave a lasting impression on their audience.